Innovative & Efficient Shotblasting Magnet

Ceramic Powered Continuous Discharge Magnet

The Fusion was built to be a lower cost but almost equally effective alternative to our Theta sweeper, it features a 22lb capacity debris tray that can be emptied right back into your shot blaster once the tray gets filled up. The Fusion weighs in at only 35lbs, making it significantly lighter than the industry standard rolling magnets allowing for more use with less effort. The design of the C8 ceramic magnet assembly creates a concentrated field which allows the Fusion to perform at the same level as the Theta. There are two concentrated points in the field, marked on the debris tray handle that are the optimal points to pull shot out of control joints up to 1” deep.

Because the magnet is always being cleaned, it maintains full power so it doesn’t leave shot behind as you collect more shot like the standard rolling magnets can when they lose power as you fill the magnet with shot; this results in a cleaner floor and a better finish.

Get prices, specs, photos, videos, reviews and more...

Light & Easy to Use. Super Strong But Light!

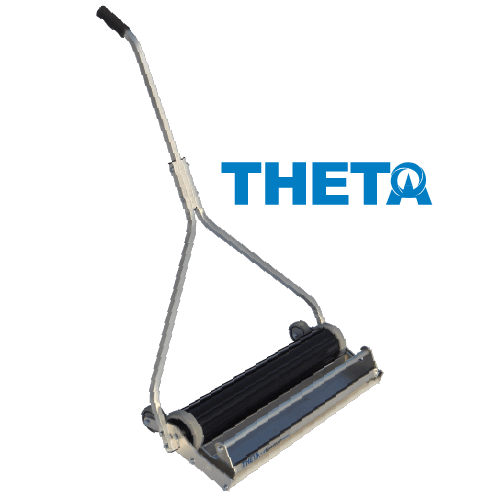

The Theta magnetic sweeper is specifically designed for heavy use by shotblasters who need to pick up steel shot of all sizes.

The Theta is light and easy to use so you can get the job done faster. This sweeper is so easy to use that it turns an undesirable job into one that no one minds doing. It’s like using a power circular saw versus a handsaw.

The Theta is much lighter then most conventional sweepers because it uses rare earth magnets. It is only 21 pounds, making for less tiring work.

Get prices, specs, photos, videos, reviews and more...

Easy to Use Ceramic Powered Shot Blasting Magnet for Medium-Large Sites

The Gamma continuous discharge magnetic sweeper for shotblasting is a cost effective and easy way to reduce time and cost of cleaning up after surface preparation jobs. The Gamma has 42lbs of shot carrying capacity and works as fast as you can walk thanks to the Ripwhirl technology that always keeps the magnet at 100% power.

Clutched drive wheels that roll on sealed precision bearings ensure the Gamma pushes easily and can take zero point turns without the risk of metal dust contaminating the bearings. The front caster wheel supports the magnet weight and allows turning without having to lift the magnet to pivot.

The specially designed C8 ceramic magnet assembly will pull S550 shot out of cracks up to 1 ¼” deep and never loses charge. Power of the magnet is concentrated in two places which is indicated by markers on the chassis for cleaning cracks while the rest of the magnet can easily pull all shot from hard surfaces on the FIRST pass.

Get prices, specs, photos, videos, reviews and more...

Double the Power in a Compact Size. The Quicker Picker Upper!

The Fission has twice as much rare earth magnets as the Theta Series enabling maximum performance to pickup up steel shot out of expansion joints and cracks.

The Fission tray is twice as big as the Theta Series tray and holds approximately 42lbs of steel shot allowing you to cover a larger area before emptying the tray.

Specifically designed for heavy use by shotblasters and surface preparation operators who need to pick up steel shot.

Get prices, specs, photos, videos, reviews and more...

Light Weight and Maneuverable Rare Earth Powered Continuous Discharge Magnetic Sweeper

The Quantum magnetic sweeper is the rare earth powered variant that shares the same chassis as the Gamma magnet, the Super Blue rare earth magnet assembly in the Quantum can pull S550 shot out of control joints and cracks up to 1 ¾” deep.

Clutched drive wheels and front caster wheel with precision bearings allow for pivot turns that drive the finned PVC drum that deposits the collected shot into the debris tray. Ripwhirl technology keeps the magnet cleaned off to maintain maximum pulling power to allow for effective pickup rates at any speed until the on board 42lb debris tray reaches capacity.

Make cleanup after shot blasting operations faster and more thorough while also reducing operator effort using a magnetic sweeper that works at your pace.

Get prices, specs, photos, videos, reviews and more...

Economical Ceramic Powered Continuous Discharge Shotblast Cleaning Solution

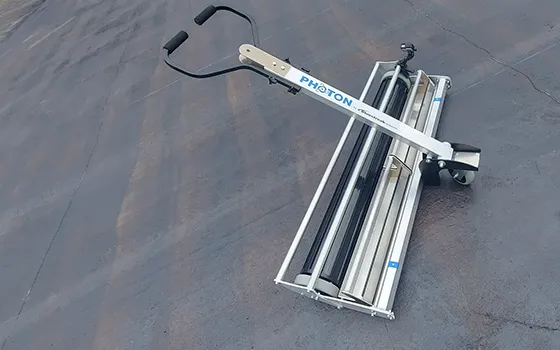

The Photon Ceramic Magnet for Shot Blasting is a premium yet cost-effective option for cleaning up after large shotblasting / surface prep operations. The ceramic magnet assembly can pull S550 shot out of control joints that are up to 1 ¼” inches deep. All the features that make the ATMOS model the industry standard for shotblasting magnets are present on the Photon, but now with C8 Ceramic power and a lower price point.

Ripwhirl technology keeps the magnetic field of the Photon clear of shot so all the magnetic power can be used to pick up shot which allows 100% shot collection until the debris bins fill up. The Photon cleans up shot at walking speed and can be converted to a towable magnet to further increase shot pickup speed.

Removable aluminum debris trays hold up to 84 lbs of S550 shot before they can be removed to empty out back into your shot blaster. This carrying capacity can be doubled by purchasing two additional debris trays that rest on aluminum rails above the PVC drum for more sweeping range.

Get prices, specs, photos, videos, reviews and more...

Cover a Lot of Ground & Pick Up Steel Shot Faster. Flexible Design for Double Duty!

The Atmos magnetic sweeper is a continuous discharge sweeper that is designed for picking up steel shot and covering large areas fast. It has the largest sweeping width at 50" and 2 debris trays that hold 84 lbs of shot.

The most unique feature of this sweeper is the flexible design. Operators can either push the sweeper like a regular push type magnet or flip the handle and use the sweeper as a tow behind sweeper that can be attached to your vehicles or equipment.

Get prices, specs, photos, videos, reviews and more...

Edger Accessories for Continuous Discharge Magnets

Edger Accessory for Theta and Fusion Shotblast Magnets

The Edger accessory can be attached to a Theta or Fusion to clean up areas more thoroughly and efficiently after shotblasting. The Edger uses an array of rare earth magnets to pick up shot that is up against walls and edges and uses rotating fins to throw the shot into the path of the main magnet housing of the Theta or Fusion This extra sweeping reach enhances the cleaning potential of the Theta or Fusion shotblast magnet by allowing operators to clean shot away from walls without using a broom.

Edger XL Accessory for Quantum Shotblast Magnet

The Edger XL accessory works similarly to the smaller Edger but with more magnetic power and a larger rotating drum. The Edger XL uses rare earth magnets to pull shot away from walls and edges of areas that have been shotblasted. There is a thermoplastic rubberized wheel on the Edger XL’s drum that rides on the wall to rotate the fins on the bottom of the Edger magnet housing to throw the shot into the path of the Quantum’s main sweeping assembly to be picked up. The Edger XL has a caster wheel for easy maneuvering and to keep a set sweeping height for maximum shot pickup. It can also be flipped up and away when not needed for easy transport and storage.

Quick Tips

What do the staff of Bluestreak have to say about Continuous Discharge magnets?

Continuous discharge magnets are really the Cadillac or Ferarri of magnetic sweepers if they work for your application..

Joe - Bluestreak Equipment

Shipping Costs & Methods

Shipping Options

Shipping options and charges available at checkout.

Real-Time Shipping Rates

Shipping rates are calculated by connecting directly to shipping carriers, giving you real time shipping quotes when you order online.

International Shipping

Some international orders outside North America may require a freight quote on checkout before the order can be completed.

Payment Methods

Know what you need for your next project?

The maximum lifting height of the Continuous Discharge Magnet Models are as follows;

Fusion | 1 inch out of cracks

Theta | 1 inch

Gamma | 1 and 1/4 inch

Fission | 1 and 3/4 inches

Quantum | - 1 and 3/4 inch

Photon | 1 and 1/4 inches

Atmos | 1 and 3/4 inches

For more information on Pickup Power follow this link: “Measuring Pickup Power and Performance in Magnetic Sweepers”

The Evolution of Magnetic Sweepers for Picking up Steel Shot

Picking up Steel Shot Just Got Faster & Easier!

Bluestreak’s Continuous Discharge line of magnetic sweepers are the evolution in magnetic sweepers that are designed to pick up steel shot because they are faster, more efficient and easier to use.

They are designed with Bluestreak's patented "Ripwhirl Technology" to continuously clean shot off the magnetic drum and deposit it into an on board removable debris tray as you push the sweeper. Because the shot is continually being cleaned off the magnet as you move the magnet forward, the magnet operates at 100% full strength all the time.

When the debris tray is full, you can see it’s full, and you just grab it and dump it. If you do end up spilling steel shot all over the magnetic sweeper it doesn’t matter because the magnet is contained in the sealed cylindrical drum, you can dump shot all over it.

The Problem with Traditional Style Magnetic Sweepers.

Traditional style magnetic sweepers with debris release levers are often used by shot blasters but they are not designed for the shot application and so they are often inefficient and tiring to use for shot blasting.

When using these sweepers the operator pushes the sweeper until the bottom is so full of steel shot that the person starts seeing that it just isn’t picking shot up anymore. They then stop picking up shot and push the magnetic sweeper onto a piece of cardboard or some other thing and pull the release lever to dump the steel shot. Then they pick up the cardboard with the steel shot on it and dump it back into some bin or hopper.

The problem is that the sweeper gradually loses pickup power as it gets packed full of shot. Less and less shot gets picked up and the operator is never sure when the magnet needs cleaning off. The operator usually has to go over the same area several times in a haphazard manner to get 100% of the shot.

Another problem is that the steel shot gets on top of the magnet and prevents the magnet housing from sitting properly and flatly on the pan separating the magnet from the shot thus putting even more distance between the magnet and the steel shot and thereby reducing the magnet effectiveness as more and more shot accumulates on top of the magnet.

That is why these traditional style magnetic sweepers do not offer the best solution for shot blasters.

The Best Solution for Picking Up Steel Shot is a Continuous Discharge System

Continuous Discharge Magnets are designed to solve the problems associated with picking up shot. Continuous Discharge Sweepers solve the problems by:

Always Operating at Maximum Pickup Strength - Because they use the "Ripwhirl Technology" the shot is continuously being discharged off the magnet so the sweepers have 100% pickup power and are cleaning at 100% power at all times instead of the gradually reducing pickup power of standard sweepers.

Reducing Operator Fatigue - Using these sweepers makes picking up shot much easier and less tiring. All the shot collects in an on board debris bin that makes it easy to see when it's full and easy to remove and dump out.

Having a Completely Sealed Magnet - The sweepers have a completely sealed magnet housing to ensure the magnetic sweeper stays effective at all times, instead of the regular magnets that end up less effective because they are covered in steel shot.

Using Super Strong Rare Earth Magnets - The continuous discharge sweepers use Super Strong N42 Rare Earth Magnets that are permanently charged instead of ceramic magnets.

Demonstration of the Atmos Continuous Discharge System

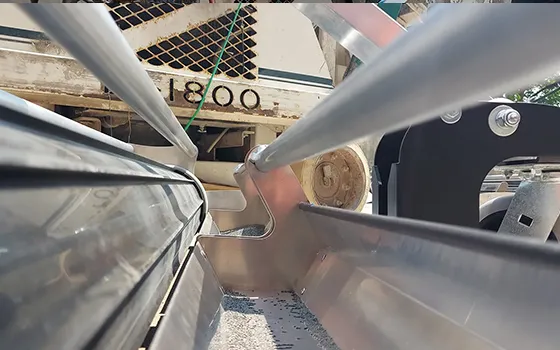

A Closeup view of the Ripwhirl Design Continuously Discharging the Shot off the Magnet

Manufacturing In-House

All of our products are designed and manufactured on site at our facilities in Ontario, Canada.

Application-Driven Design

We have manufactured and developed application driven magnetic products since 2005.

Working from Rural Roots

Working from rural southern Ontario, our business has grown and now sprawls over several properties using former agricultural buildings.

Made In Canada

All products proudly designed and manufactured in Canada

(since 2005).

No Border Issues

We handle U.S. customs clearance so you don’t have to.

Pay only the charges identified at checkout.

All Items In Stock

All products are stocked for quick shipping and delivery.

Fusion

Fusion Theta

Theta Fission

Fission